REV™ uses a combination of Vacuum & Microwave energy, which results in a rapid, gentle drying process. By controlling the pressure and microwave power density, one can effectively control both the temperature and the final moisture of the product. Adding microwave energy to the drying process allows for an efficient energy transfer where the energy is absorbed by the material volumetrically, promoting a uniform dehydration process.

REV™とは?

REV™ stands for “Radiant Energy Vacuum.” It’s our own patented process of vacuum microwave drying that dehydrates food and plants more efficiently and of a higher quality than ever before.

See the results in person!

Book a Discovery Call today.

The benefits of REV drying

Efficient, gentle drying

Suitable for nearly every organic material

Precise moisture control

Closed-loop, volumetric drying

Less waste

Upcycle lower grades and reduce microbes

Superior quality retention

Keep natural colors, flavors, and nutrients

Optimized floor space

Use a fraction of the space of other drying methods

Minimal carbon footprint

Zero hazardous materials, zero chemicals, zero GHG emissions

From fresh to dry in hours, not days.

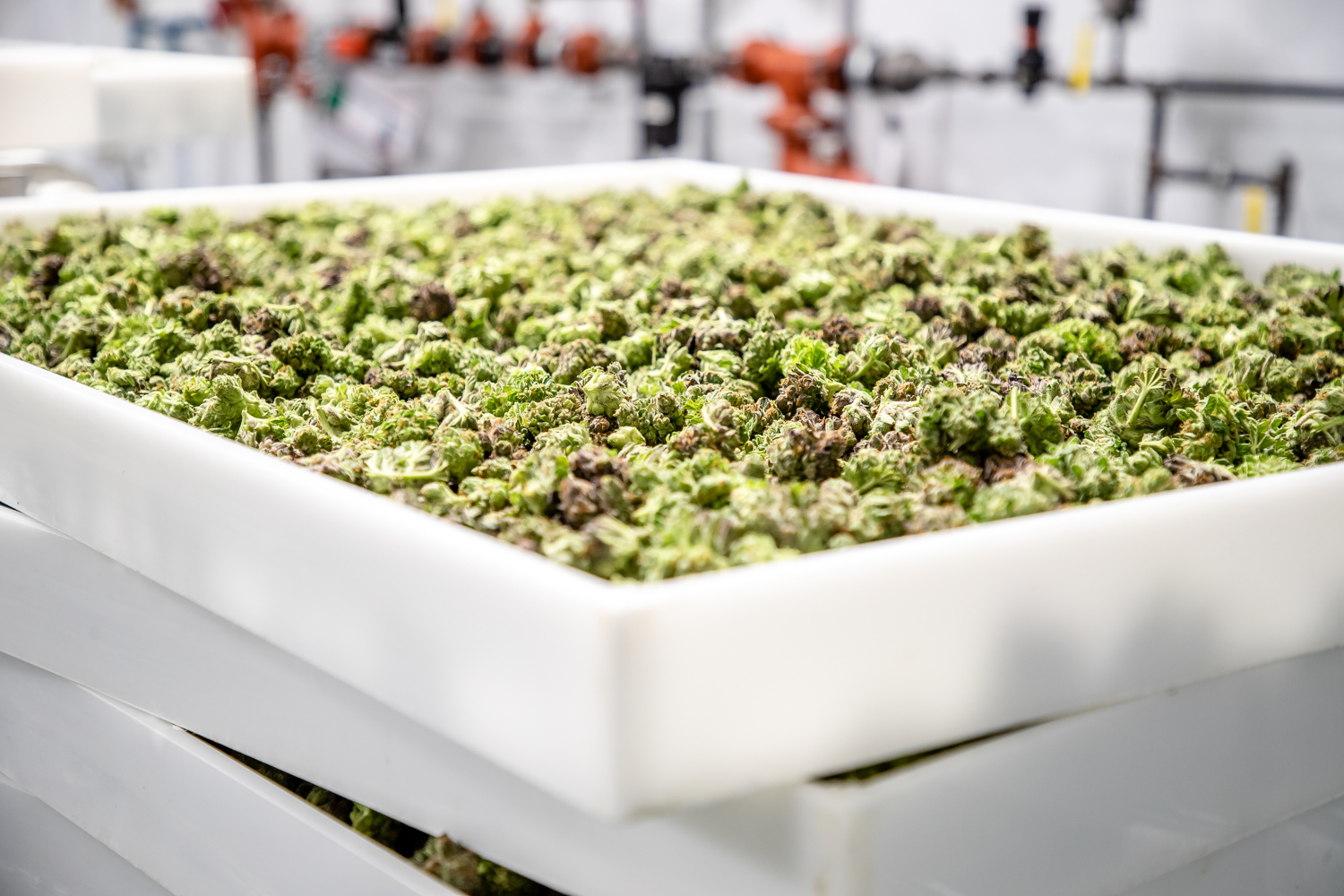

But don’t take our word for it. See before and after images below.

How does REV drying work?

Radiant Energy

- Fast and uniform volumetric heating

- Precise temperature regulation, process control and customization

- Fresh to dry in a fraction of the time

Vacuum

-

Lower boiling point for efficient,

low-temp processing - Quick dehydration without cooking

- Closed system captures volatilized components

- Add a pleasing puff to your products

REV-Dried

Strawberries

Moisture level: 40%

Drying time: 30 mins

Use: Snacks, Ingredients

EnWave gives you two ways to dry

タンブル乾燥

真空マイクロ波チャンバー内の回転ドラムの中で製品を転がせば、正確な残留水分率で迅速かつ安定した脱水ができます。よりボリュームのある果物、野菜、穀物、乳製品の脱水、ドライフルーツ、肉、乳製品、スパイスの製造に最適です。さらに、統合HMIとPLCシステムにより、より大きな制御が可能です。

トレイ乾燥

デリケートな製品を、乾燥室内を連続的に移動する電子レンジ用透明トレイでやさしく乾燥します。常圧下での出し入れは素早く簡単です。REVトレー乾燥は、壊れやすい果物や花、複雑な焼き菓子、砕けやすい乳製品に最適です。

REV technology scales with your business

BEST FOR

R&D and small-scale producers

REV10 kW

Freq: 2450 mHz Vacuum: 12-300 Torr Size: 7.9 x 5.8 ft (2.4 x 1.8 m) Ceiling: 10 ft (3.1 m)

BEST FOR

large-scale producers

REV60 kW

Freq: 2450 mHz Vacuum: 25-300 Torr Size: 38.3 x 12.5 ft (12.2 x 4.6m) Ceiling: 15 ft (4.6 m)

BEST FOR

industry leaders

REV100 & REV120 kW

Freq: 2450 mHz Vacuum: 22-300 Torr Size: 55.7 x 14.8 ft (16.6 x 4.6 m) Ceiling: 15 ft (4.6 m)