What is Volumetric Heating?

In food processing, innovative technologies are constantly emerging to improve efficiency, product quality, and sustainability. One such groundbreaking method is volumetric heating, a process that’s transforming the way we approach food preservation and processing. At EnWave, we’re proud to be at the forefront of this revolution with our Radiant Energy Vacuum (REV™) technology. Understand volumetric heating and discover how it’s shaping the future of food production.

What is Volumetric Heating?

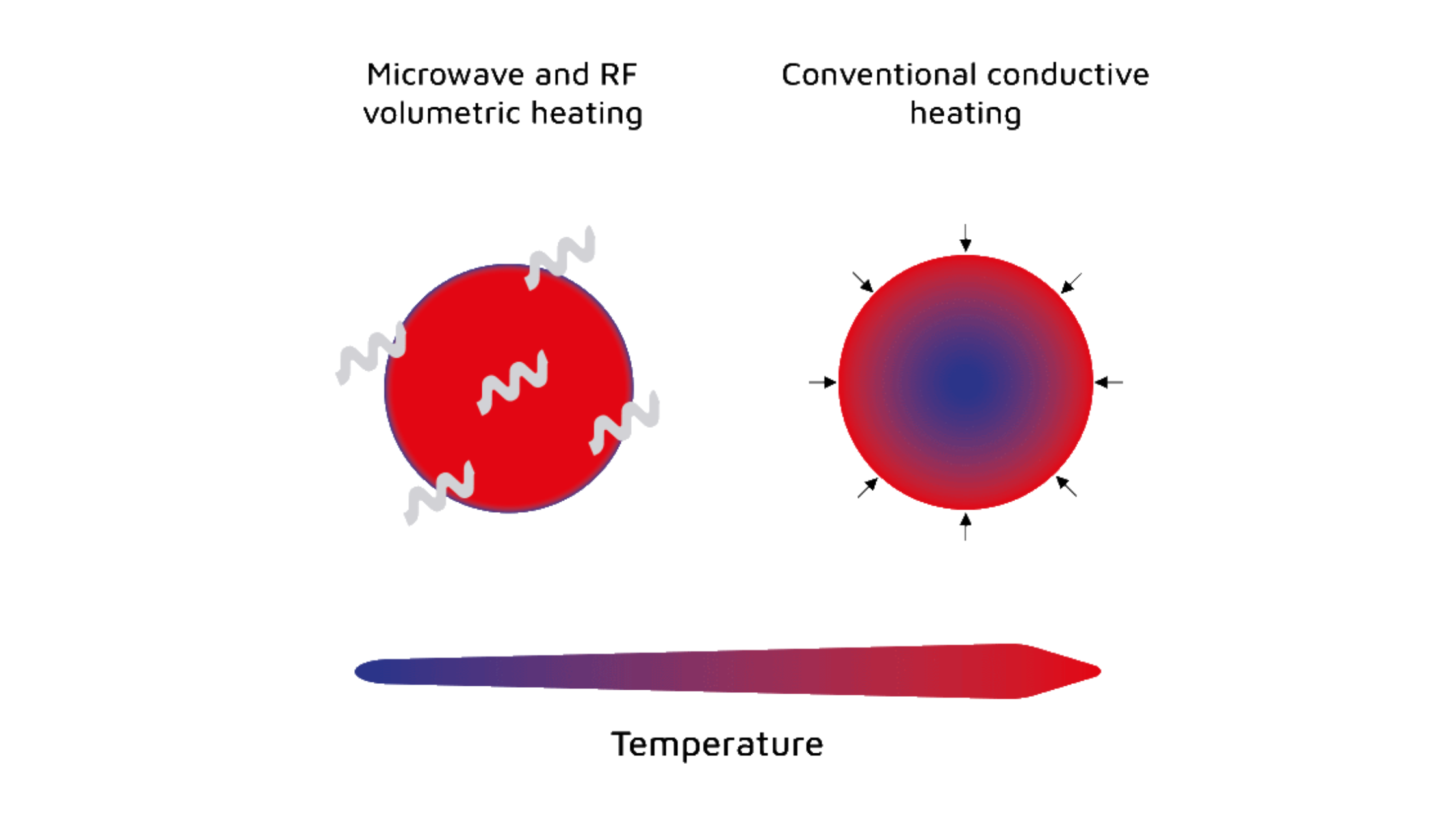

Volumetric heating is a method that allows for the uniform heating of an entire volume of material, whether it’s a liquid, suspension, or semi-solid. Unlike traditional heating methods that rely on conduction from hot surfaces, volumetric heating penetrates the entire body of the material, delivering energy evenly throughout.

This innovative approach offers several advantages over conventional heating methods:

- Uniform heating: Every part of the product receives equal energy, ensuring consistent results.

- Faster processing: The direct energy transfer leads to quicker heating times.

- Improved quality: By avoiding hot spots and minimizing thermal damage, volumetric heating helps preserve the product’s natural characteristics.

How Volumetric Heating Works

The process of volumetric heating is based on the principle of energy transfer at a molecular level. Here’s a step-by-step breakdown of how it works:

- Energy Application: Electromagnetic energy, typically in the form of microwaves, is applied to the product.

- Molecular Agitation: The energy causes water molecules within the product to vibrate rapidly.

- Friction Generation: This molecular movement creates friction, which in turn generates heat throughout the product.

- Uniform Temperature Rise: Because the energy penetrates the entire volume, the temperature rises uniformly across the product.

- Precise Control: The amount of energy applied can be carefully controlled, allowing for precise temperature management.

This process delivers multiple critical advantages for food and ingredient processing. By minimizing thermal damage to functional components, the technology ensures superior preservation of nutritional integrity. The system’s ability to reduce fouling risk, even when handling thick or viscous products, enhances operational efficiency. Moreover, its precise temperature control mechanism, achieved through sophisticated flow rate adjustments, allows for unprecedented accuracy in processing delicate ingredients, ultimately maintaining the highest quality standards throughout production.

Different Ways to Achieve Volumetric Heating

While microwave energy is a common method for achieving volumetric heating, there are other approaches as well. Here are some of the primary techniques:

- Microwave Volumetric Heating (MVH): This method uses microwave energy to heat products as they flow through a treatment chamber.

- Radio Frequency (RF) Heating: Similar to microwave heating, RF uses lower frequency electromagnetic waves to heat products volumetrically.

- Induction Heating: While primarily used for heating metals, induction can provide volumetric heating for some conductive materials.

- Ohmic Heating: This method passes an electric current through the product, generating heat throughout its volume.

Each of these methods has its own strengths and is suited to different applications. At EnWave, we’ve harnessed the power of microwave energy in our REV™ technology to provide superior volumetric heating for food processing.

Harnessing Volumetric Heating for Superior Results

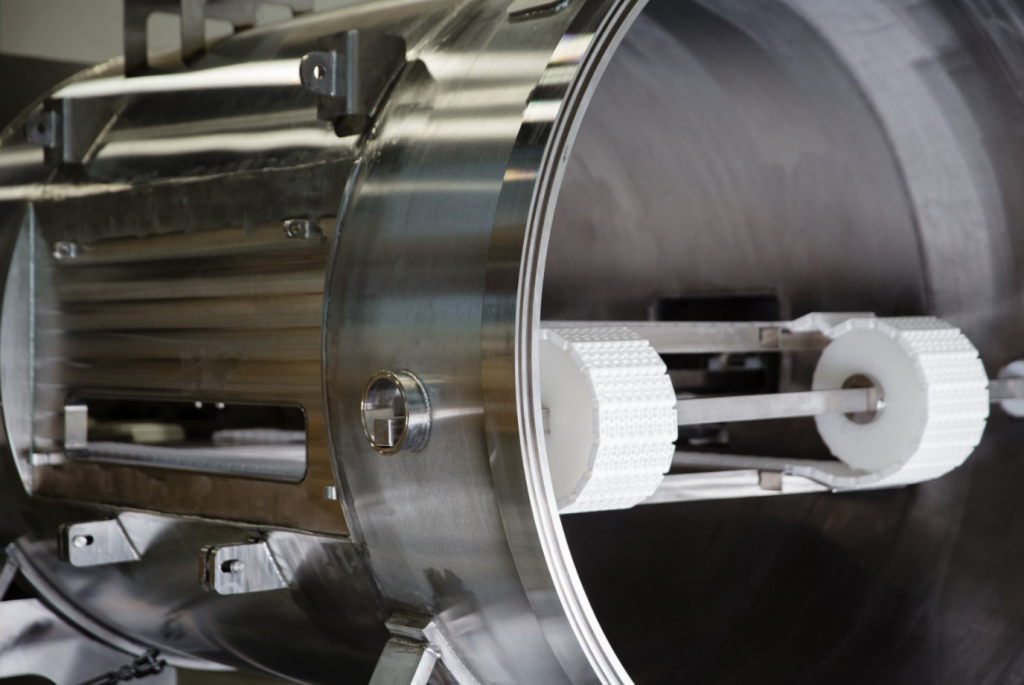

EnWave’s Radiant Energy Vacuum (REV™) technology represents a significant leap forward in the application of volumetric heating for food processing. By combining microwave energy with a vacuum environment, REV™ offers unique advantages that set it apart from other drying methods.

Here’s how REV™ leverages volumetric heating:

- Vacuum Creation: The process begins by creating a vacuum environment, which lowers the boiling point of water in the product.

- Microwave Energy Application: Precisely controlled microwave energy is then applied to the product.

- Volumetric Heating: The microwave energy penetrates the entire volume of the product, causing water molecules to vibrate and generate heat uniformly.

- Rapid, Low-Temperature Drying: The combination of vacuum and volumetric heating allows for quick moisture removal at lower temperatures than traditional methods.

The benefits of this approach are numerous:

- Preservation of Heat-Sensitive Compounds: The low-temperature process helps maintain the integrity of vitamins, antioxidants, and other valuable nutrients.

- Improved Texture and Appearance: The rapid, uniform drying helps preserve the product’s structure, resulting in better texture and visual appeal.

- Enhanced Flavor Retention: By avoiding prolonged exposure to heat, REV™ technology helps lock in the natural flavors of the product.

- Increased Efficiency: The volumetric heating approach significantly reduces processing times compared to traditional drying methods.

- Flexible Moisture Content: REV™ allows for precise control over the final moisture content of the product, enabling the creation of everything from crispy snacks to chewy dried fruits.

As the food industry continues to evolve, the demand for efficient, high-quality processing methods is only going to grow. Volumetric heating, particularly as implemented in EnWave’s REV™ technology, offers a solution that meets these needs while also addressing concerns about sustainability and product quality.

By reducing processing times, lowering energy consumption, and preserving the natural characteristics of food products, volumetric heating is poised to play a crucial role in shaping the future of food processing.

If you’re intrigued by the possibilities of volumetric heating and how it could transform your food processing operations, we invite you to explore EnWave’s REV™ technology. Our team of experts is ready to help you discover how this innovative approach can benefit your specific products and processes. Contact EnWave today to schedule a consultation and learn how REV™ technology can revolutionize your production process.